GOLDSCHMIDT-THERMIT - More safety for the rail: TracksafeRelease

The importance of monitoring the railroads as a transport system has been known not only since the spectacular accidents and near-accidents involving Germany's flagship railroad, the ICE. However, it is not only the rolling stock that requires constant and, due to the high volume of traffic, ever-increasing monitoring; the railways as a supporting pillar of the infrastructure require it in the same way. Various methods are available for this purpose, including the taking of material samples. The most reliable technology, which does not damage the rail, comes from the company Goldschmidt-Thermit. This uses a patented electromagnetic method that measures tensile and compressive stresses in the rail strands and thus indicates the repairs needed to ensure driving safety.

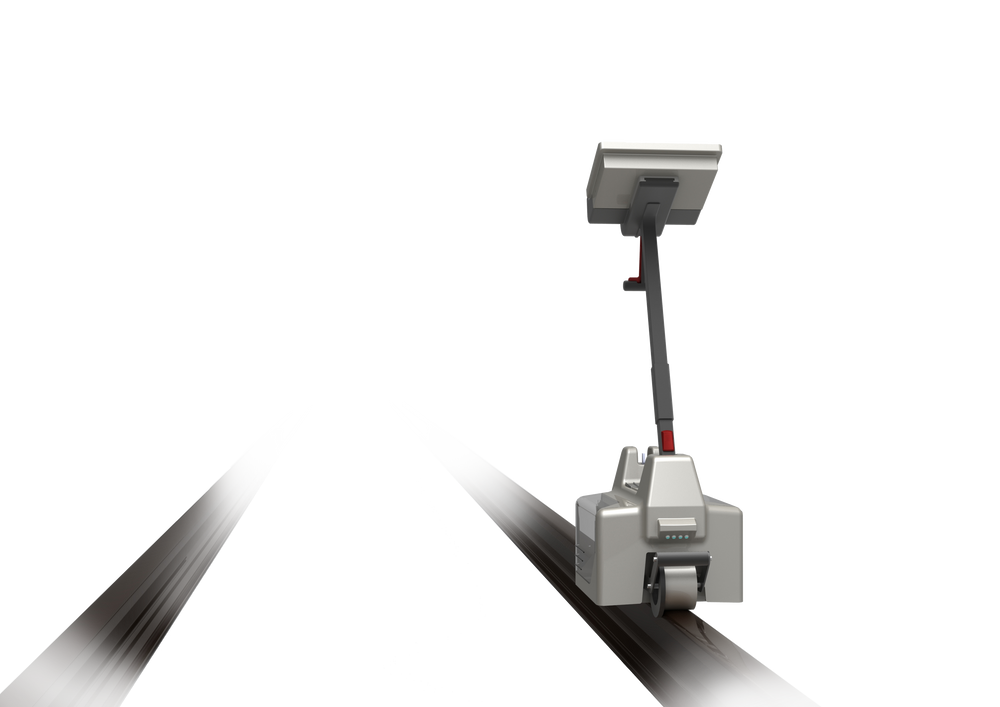

The aim of product development for the new generation of measuring devices was to design a product that is easy and safe to operate and can be used universally worldwide on all rail profiles and in all weather conditions. While the measuring technology remained unchanged, the device structure was reconfigured and communicated accordingly via the design. A comparison with the previous RailScan device makes the generation leap to TracksafeRelease more than clear.

During product development, Busse Design+Engineering carried out the design and construction concept and then realized a trade show prototype with partial functions - the result of an intensive technology transfer between Goldschmidt-Thermit, the subsidiary Metalelektro and the development partner Busse Design+Engineering. The prototype was presented to the public in September 2010 at the InnoTrans trade fair for transport technology in Berlin. The response from experts was impressive, so that this highly innovative measuring device will be transferred to series production in the near future.