Design for manufacturing

Design for Manufacturing (DFM): The perfect product begins with the concept

Design for Manufacturing (DFM): The perfect product begins with the concept

THE FINISHED PRODUCT MUST BE CONVINCING – EVERYTHING ELSE IS IRRELEVANT.

The challenge with new developments often lies in finding the right manufacturing process that takes into account cost and deadline targets as well as market-relevant quantities. At BUSSE, we help our customers realize a design that is not only aesthetically and functionally appealing, but also economically feasible to manufacture.

Thanks to our cross-industry experience and the expertise of our in-house design and engineering department, we have extensive knowledge of materials and processes as well as a broad network of suppliers. This enables us to consider manufacturing options, the associated costs, and their impact on the design as early as the design process.

To ensure that the essential subtleties of the design are not lost when it is later handed over to series production, we integrate these aspects right from the start. With our many years of experience and interdisciplinary expertise, we find the best solution at a reasonable cost.

Our range of services: More than just design

Our range of services: More than just design

Manufacturing-oriented design: Aesthetics and function in harmony with feasibility.

Design to cost: Cost efficiency as an integral part of the design process.

Quick time to market: Fast and smooth transition of your product to series production.

MVP development: Development of minimum viable products for rapid market testing.

Quantity-dependent manufacturing strategy: Tailor-made solutions for your target quantities.

Supplier research and comparison: Informed selection of the best partners.

Amortization analysis: Transparent decision-making basis for your investment.

Production-ready data: Precise data preparation for error-free production.

Well-founded handover to series suppliers: Ensuring a smooth transition.

Our DFM process: From concept to finished solution

Our DFM process: From concept to finished solution

Our work process is designed to minimize the risks of product development and ensure maximum efficiency.

Early analysis and strategy development

Based on the requirements of your briefing, we analyze potential discrepancies between design, costs, and quantities at an early stage. Thanks to our immense project diversity across a wide range of industries, we are familiar with a wide variety of manufacturing processes. This enables us to identify the appropriate strategy for every component size, material, and quantity.

Transparent decision-making

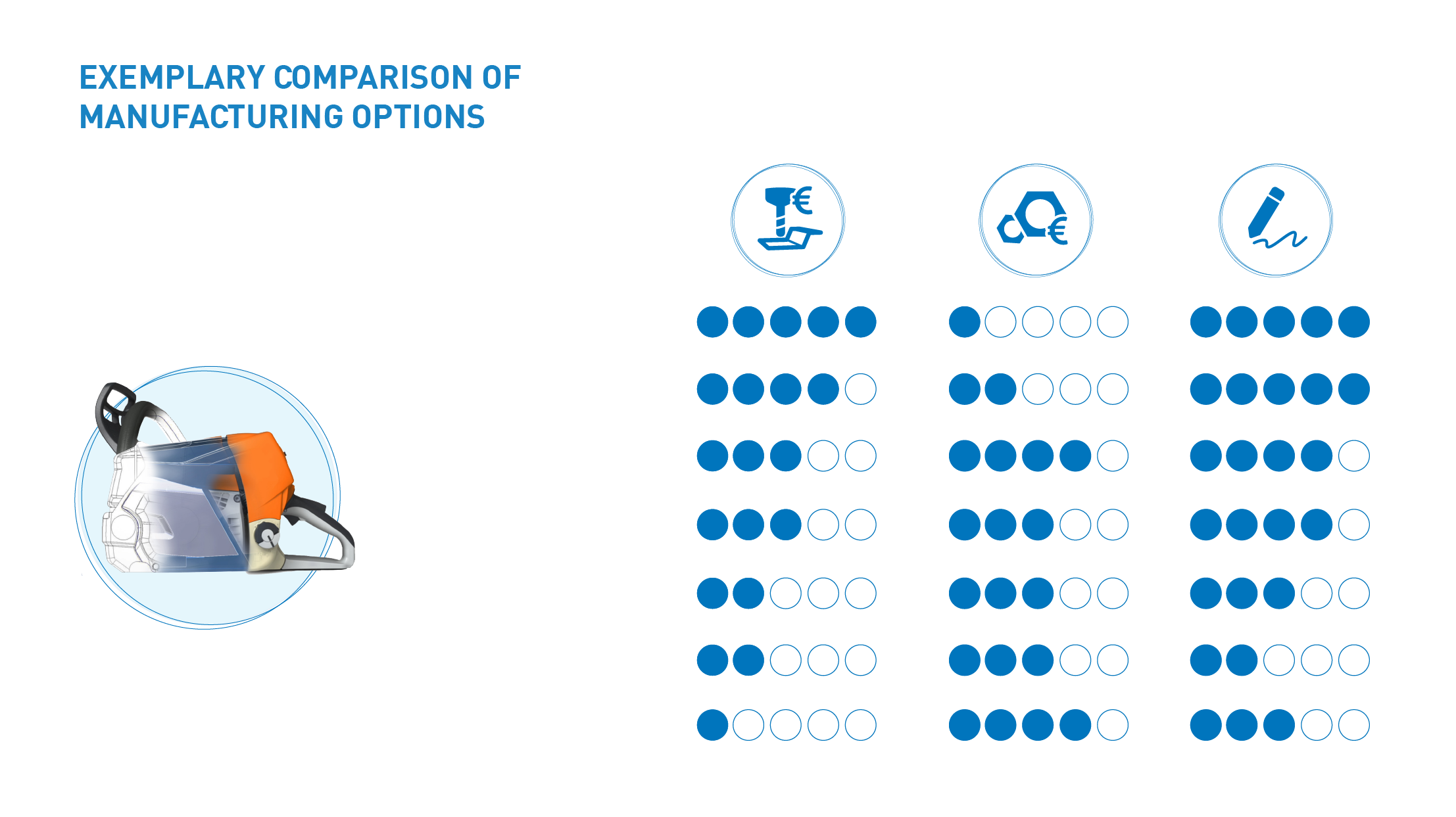

Thanks to our extensive network of suppliers and service providers, we can determine the approximate investment and unit costs based on preliminary data. We present this information in a clear format to enable you to make informed decisions. We attach great importance to transparent communication between you, potential suppliers, and us.

Detailed implementation and handover

Once the optimal process has been selected, we prepare the data with great attention to detail in accordance with the selected process. We are not only proficient in classic manufacturing processes, but also keep our finger on the pulse of the latest developments. This means we can also incorporate innovative methods such as additive manufacturing, rapid tooling, ceramic injection molding, and many more into your project as required.