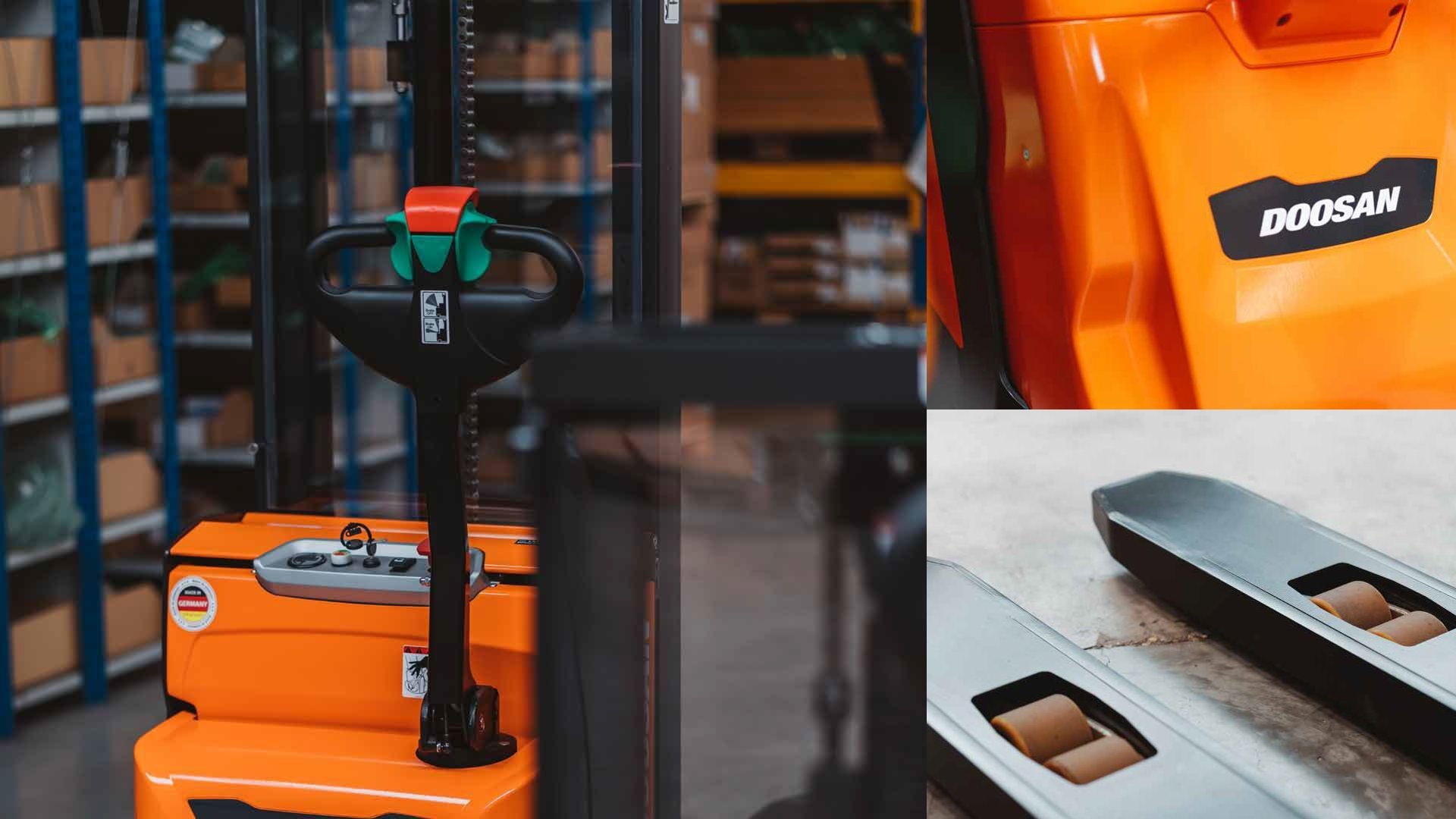

DOOSAN - Modern family design with new processes

The new products of the electric low-platform truck family from Doosan Logistics Europe GmbH are presented in a modern fresh design. With the platform low-lift truck as the latest new development, the new product family is now established on the market. We were able to support the customer, who previously worked mainly with steel, with our expertise in design and construction as well as our experience with processes and suppliers.

The new products Made in Germany of the electric low-platform truck family of Doosan Logistics Europe GmbH are characterized by extraordinary robustness and the most compact design on the market. As a partner for design, construction and consulting, we at BUSSE were able to accompany the development of the new industrial trucks from the initial concept to the implementation of production. In addition to a new, fresher design, it was also possible to significantly reduce manufacturing costs through a wide range of measures, while at the same time optimizing existing designs and integrating new features.

A particular challenge in the design process was the very narrow scope for design, which is due to the extremely compact and well thought-out construction. However, this is also one of the key USPs on the market, as it allows a minimum turning circle and an optimum view of the transported goods and the travel path.

Another issue in the development of the family design was the enormous variety of different equipment variants. Due to the size of the parts, the aim here was to produce as few different molds as possible while at the same time creating a modern and uniform appearance. This was ultimately achieved through a modular strategy and the use of common parts as well as modular molds, which was already taken into account during the design concept.

During implementation, we were able to draw on our many years of experience in manufacturing processes and our large network of suppliers. A comprehensive comparison of various possible processes with all their advantages and disadvantages ultimately led to a combination of thermoformed and TSG parts for the cladding. The latter process in particular scored points for its impressive stability and excellent dimensional accuracy at comparatively low investment costs. The production data for the molded parts was then prepared in-house in close coordination with the customer and the selected suppliers to ensure an optimum result.

With the new product family, Doosan is taking a step towards the future and further expanding its position as a major supplier of industrial trucks.