Systematic ergonomics – practical and resilient

Ergonomics is much more than theory or compliance with standards. It determines whether products work in everyday life, are accepted and remain convincing in the long term. At BUSSE Design+Engineering, the focus is therefore consistently on practical benefits and usability.

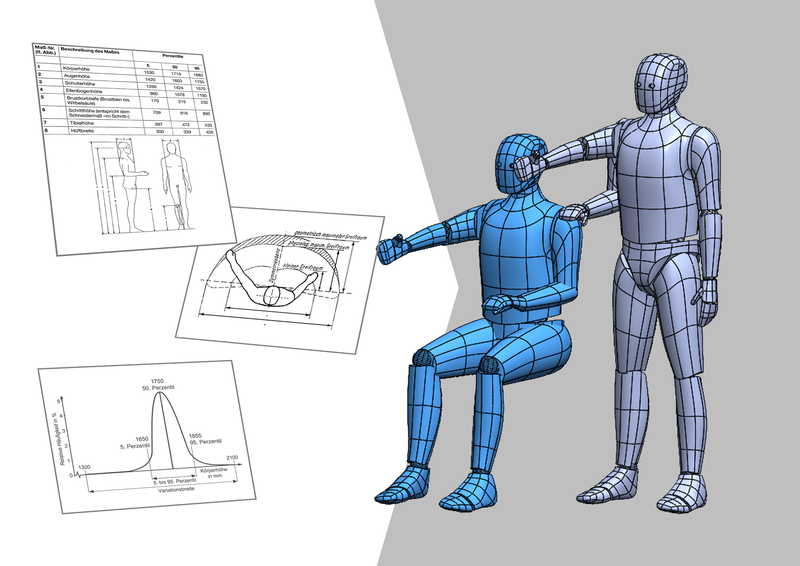

Our work is based on well-founded ergonomic databases and anthropometric specialist literature. From this, we develop user-centred working environments that not only exist on paper but also prove themselves in real-world use – from the initial concept to series production.

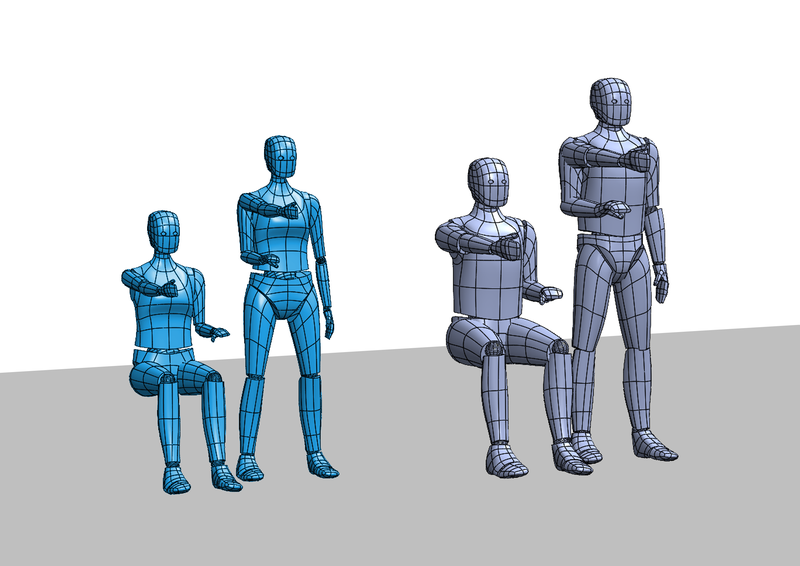

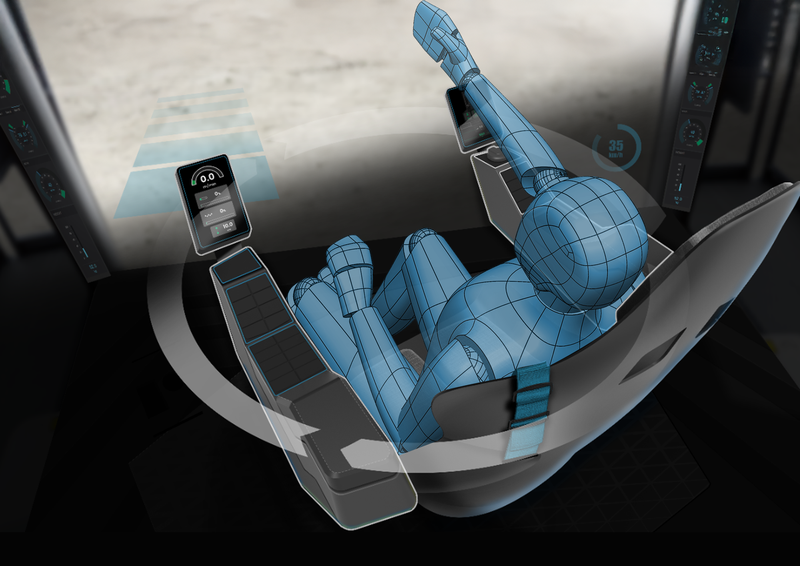

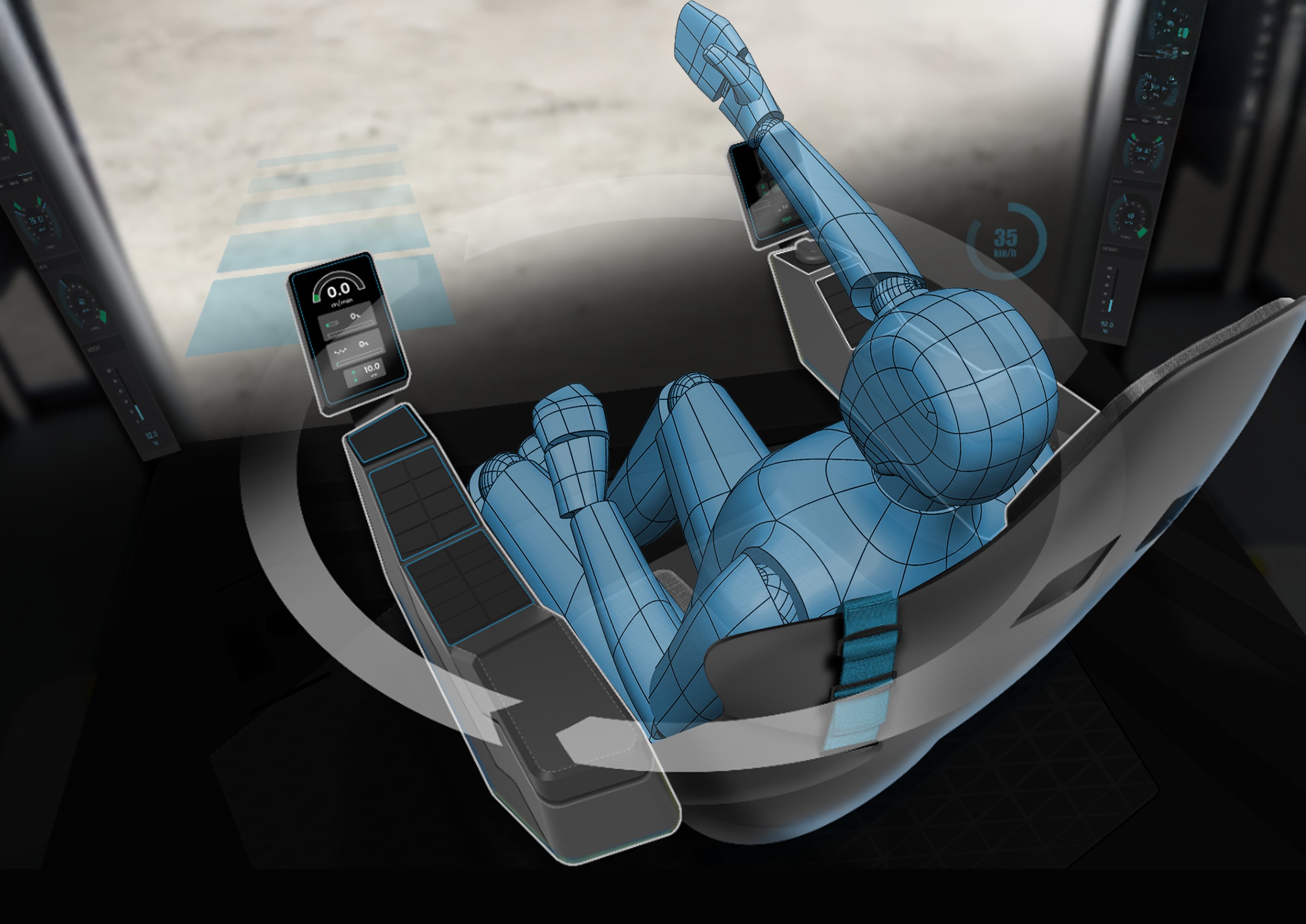

Our latest unique selling point is our specially designed 3D ergonomic dummies, which realistically represent the different percentiles of international user groups. Tables and standards have been converted into practical 3D data. We refer to renowned data sources such as the BWB's Ergonomics Handbook, MIL-STD 1472H from the DoD, ISO 9241-210 Human Centred Design Process and many more.

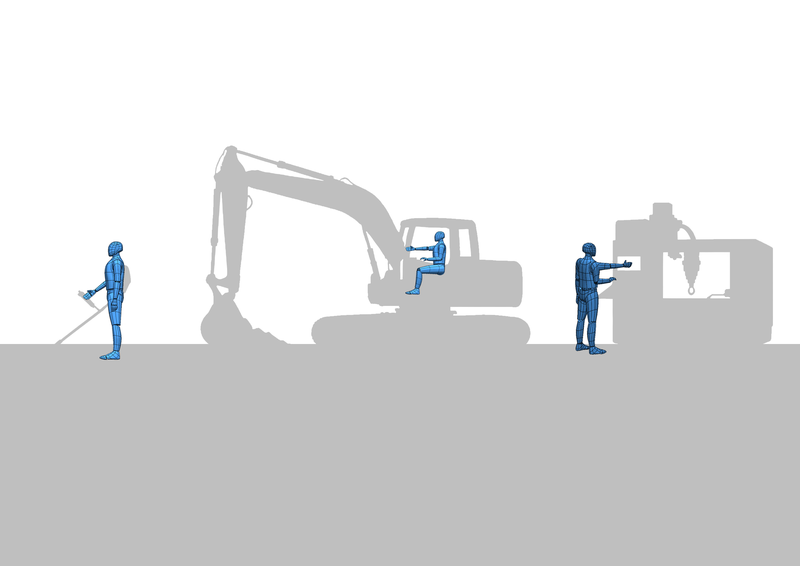

This enables us to create a robust basis for ergonomic assessments early on in the development phase in a digital context. The 3D ergonomic dummies allow specific ergonomic dimensions and conditions to be tested in the early concept phases without having to determine them in a complex physical prototype or test setup. For later project steps, where a physical setup is unavoidable, the studies with our dummies provide a valid basis.

There are currently no comparable solutions on the market that offer this combination of dimensional accuracy, anthropometric completeness and practical applicability. Many existing approaches only allow for limited or unreliable conclusions – a risk that we consciously avoid.

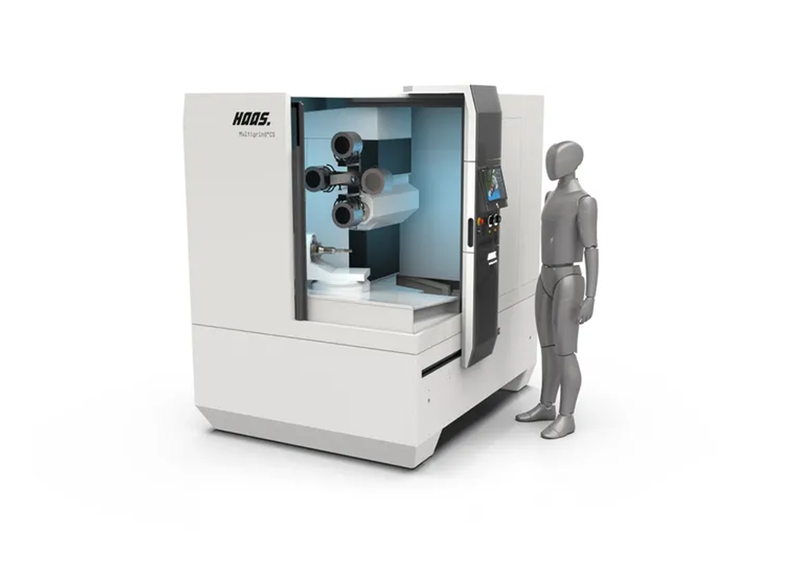

Our range of services extends from the development of complex vehicle cabins and special-purpose vehicles to control stations and console workstations to handheld devices.

In order to efficiently combine theory and practice, we have set up our own HMI Lab. In this environment, we can quickly and specifically test previously created ergonomic concepts and studies with practical setups. This allows us to validate fields of vision, reach zones, operating logic and workflows in a realistic manner at an early stage.

We document the results obtained in a professional, standard-compliant and comprehensible manner, and they can be used directly for acceptance, testing and approval processes. In this way, we create planning reliability, reduce development risks and ensure that products not only work on paper, but also perform convincingly in everyday use.