BÜHLER - A new dimension in conveying technology

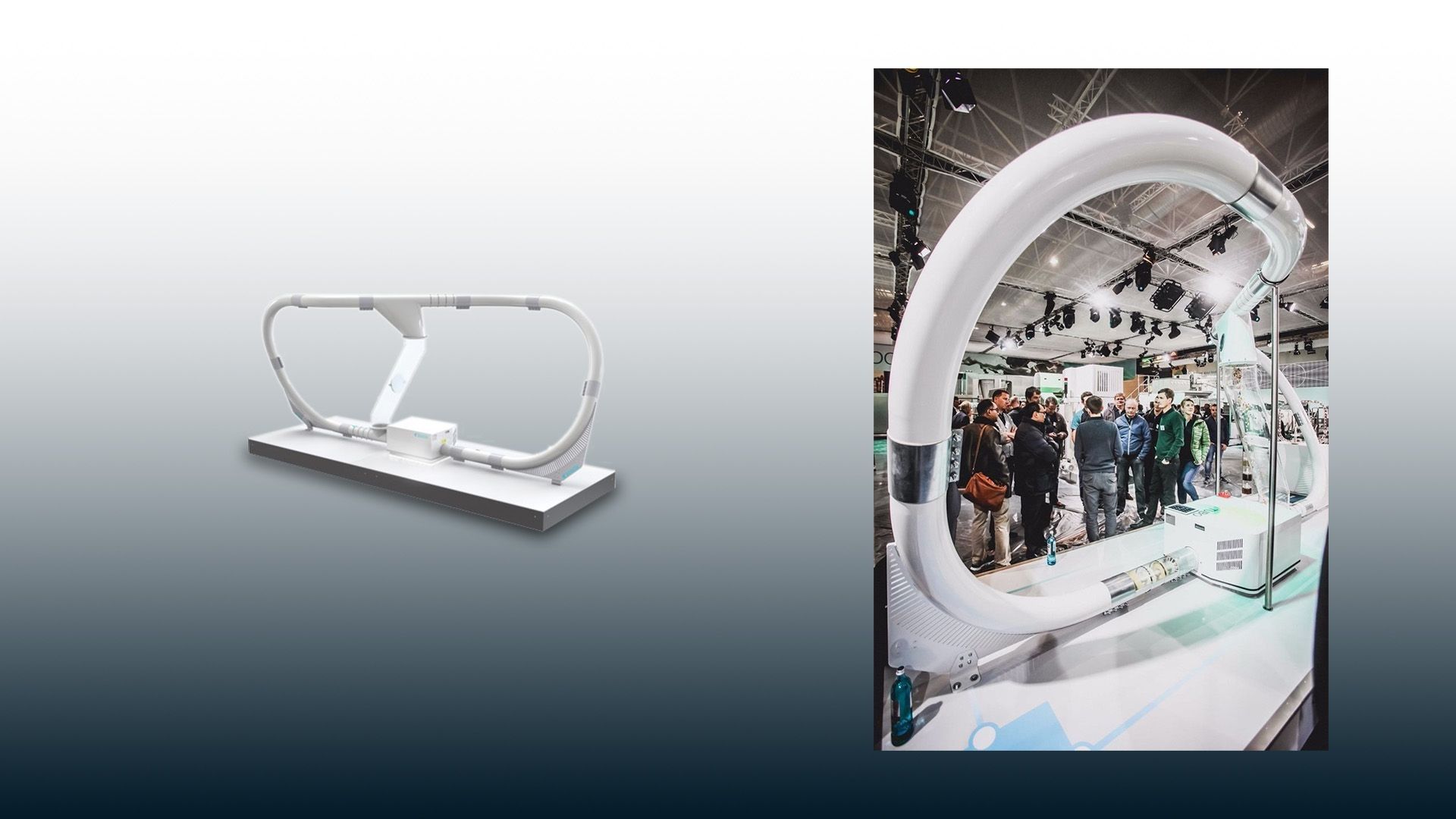

After intensive cooperation with BUSSE Design+Engineering, the time had come: Swiss-based Bühler AG, world market leader in the field of production technologies for the manufacture of foodstuffs and technical materials, presented the new TUBO conveying system at this year's bulk materials conference in Magdeburg, setting new standards in conveying technology.

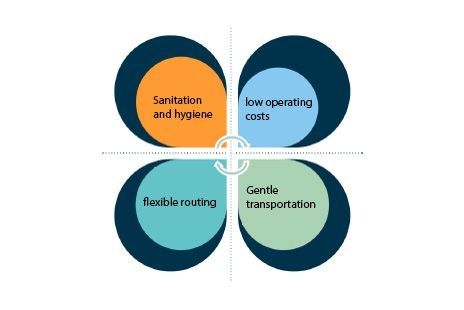

Bühler TUBO is an innovative conveying system that sets new standards in materials handling in breweries, distilleries, and industrial mills. Unlike today's systems, the bulk material is transported in a closed tube without a tension cord via TUBIT push elements. Compared to conventional conveying systems, energy consumption is massively reduced and the raw product is transported much more gently.

With TUBO, plant planning can be made considerably more flexible thanks to three-dimensional plant layouts. In addition, further advantages in terms of hygiene and safety ensure that the investment pays for itself in the shortest possible time.

Low energy consumption

Compared to conventional transport systems, TUBO significantly reduces system friction and thus energy consumption. Three-dimensional system layouts also reduce investments in the building.

Flexible system planning

With its loose push elements, TUBO enables three-dimensional transport, reduces the number of transfer points and allows flexible plant layouts with significantly reduced space requirements.

Highest standard of hygiene

TUBO ensures residue-free product conveying as well as complete emptying of the pipeline. At the same time, the TUBIT thrust elements prevent segregation of the product.

Gentle product transport

Thanks to friction-optimized product conveying, TUBO minimizes breakage and increases yield. Despite low transport speeds, high conveying volumes can be realized.

Maximum safety

TUBO's enclosed transport at low speed eliminates the need for additional explosion protection measures and thus reduces investment costs.

In addition to the construction and design of the system elements, drives and the thrust elements, BUSSE was able to support Bühler AG in this innovative project already during the initial concept phase by providing concept variants and functional models for concept suitability testing. In the detailing phase, test systems were then jointly planned, manufactured and supported at customers in the field and at trade fair facilities, and scaled to further sizes and conveying volumes. In the series transfer phase, BUSSE was also able to provide support in the preparation of all documentation as well as operating and service manuals, in addition to the preparation of the system components for tooling and production and the derivation of a modular system directly into the BÜHLER PDM system.

New sizes and operating aids are already in the pipeline. We are looking forward to continuing the - in many respects - ingenious teamwork with BÜHLER AG.