BUSSE - Case Study: Wood and forestry+

Current situation

- Use of heavy equipment such as harvesters and felling caterpillars as well as chainsaws, which in turn are guided and operated by forest workers

- Physically strenuous work and heavy equipment

- Dangerous work

- Use in sensitive nature reserves

- Remote regions

- inaccessible terrain

- Forests are a sensitive and endangered natural asset

- Forests are important as climate regulators and CO2 filters as well as ecosystems and habitats for animals (air and water protection functions and conservation of biodiversity)

Solutions

- Reduction of the burden on people, the environment and working equipment

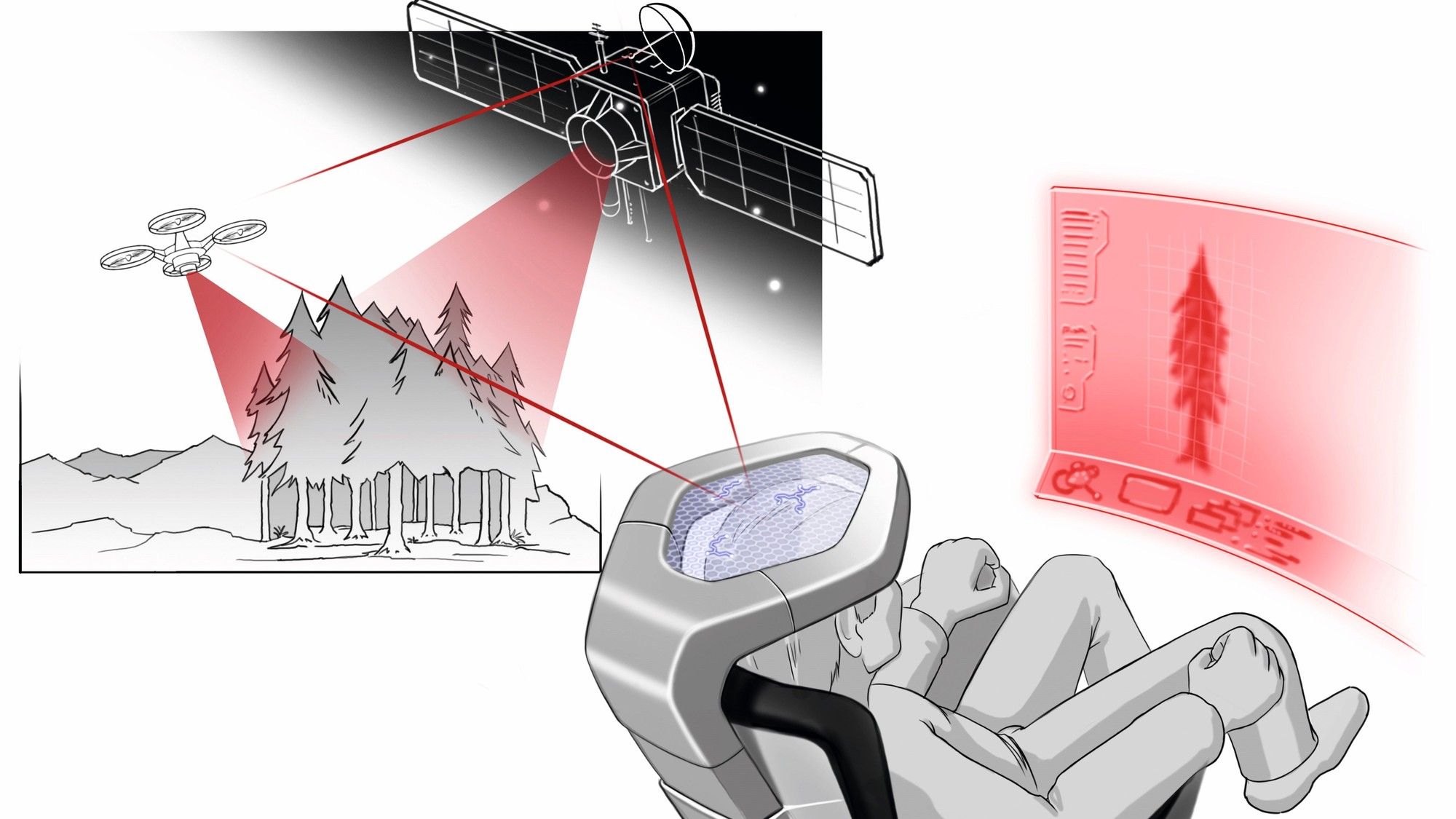

- Easier monitoring

- Unrestricted care

- The goal is a minimally invasive intervention and targeted reforestation and reforestation

- Fertilization and pest control

Forestry 2080

As part of our product visions 2080, we have looked at two important questions. One of them is the consideration of how information and technologies can be meaningfully networked in the area of application and how the work of forest workers can be supported and relieved. The other question is, what tools and vehicles could look like in the year 2080. GIS Geo-information systems already offer early detection and localisation of damage caused by pest infestation and insect feeding as well as air pollution, wind and drought. It should also be considered whether further improvements can be made to existing systems.

1. Automatic Harvesting

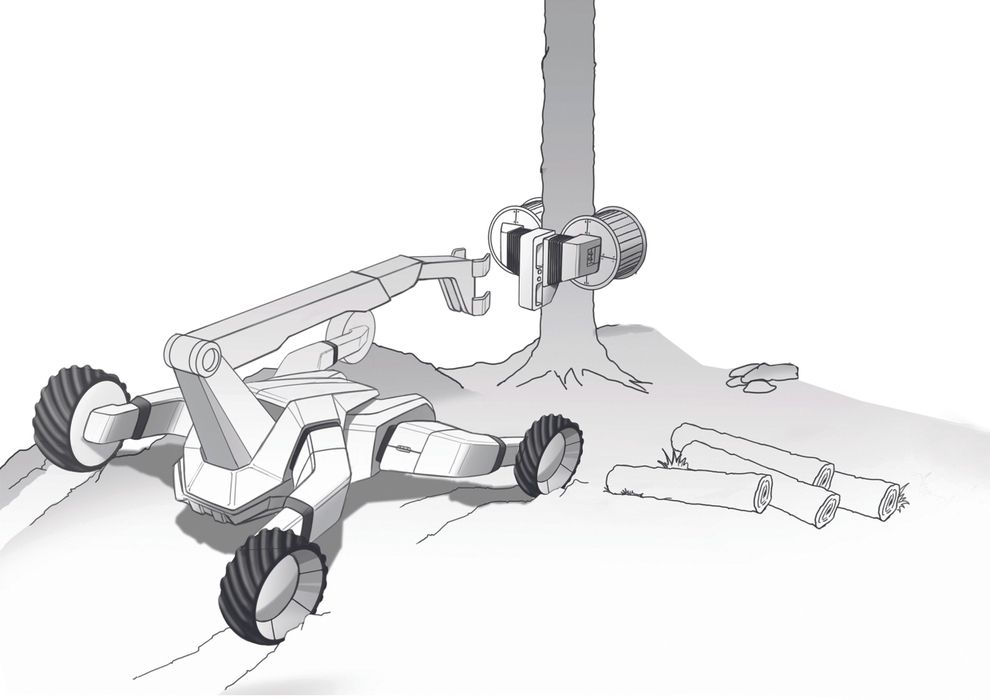

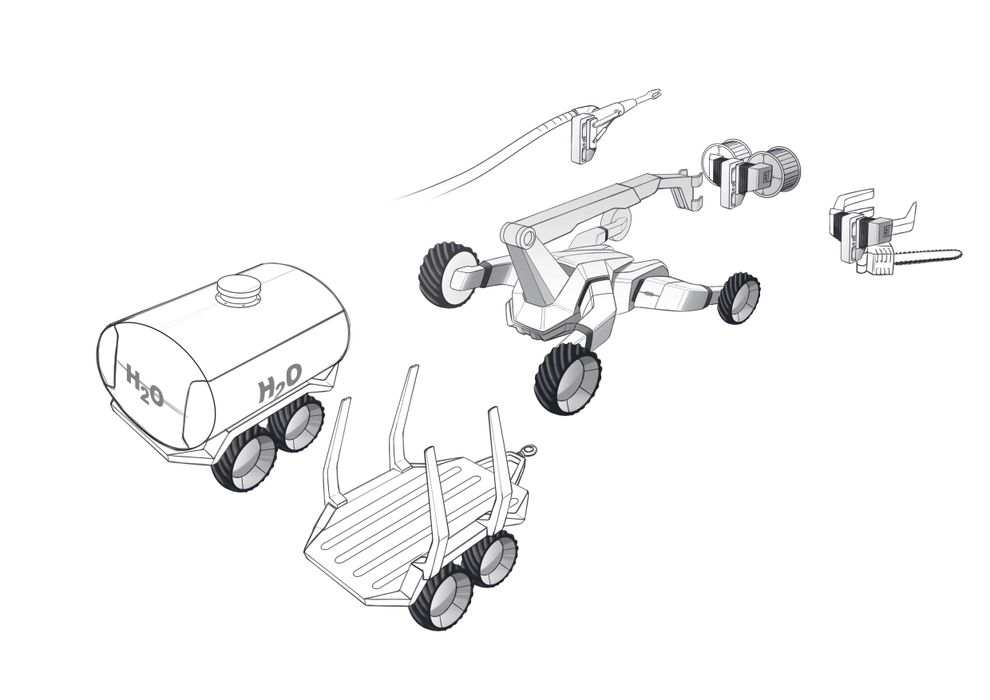

**MODULAR ALL-ROUNDER

**For various applications and work in the forest (felling, fire-fighting, working paths, cutting paths, etc...). Relevant aggregates and devices can be attached.

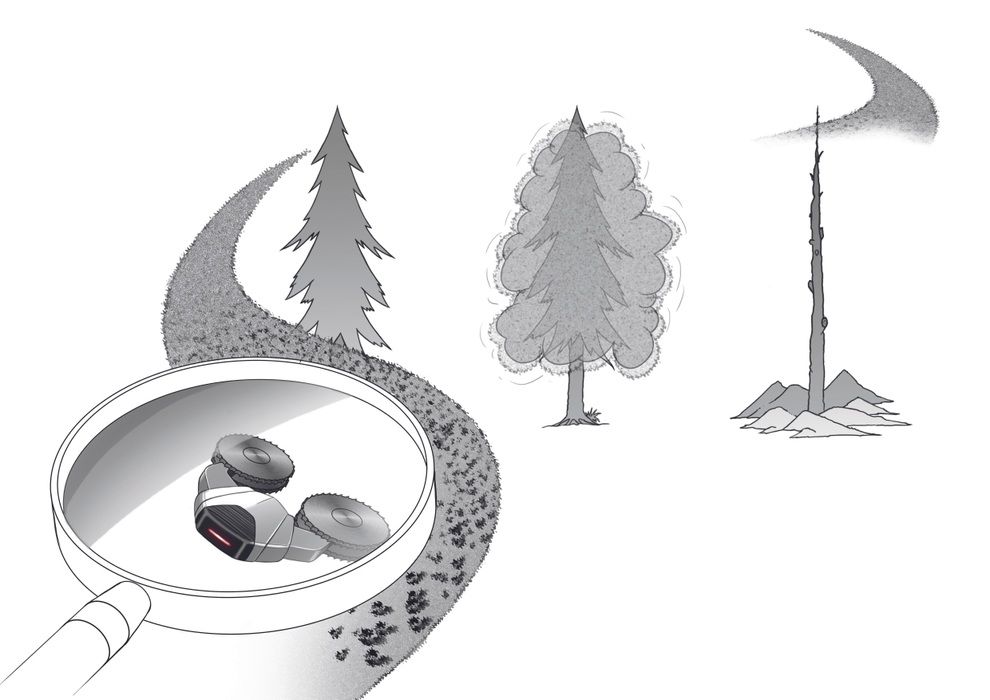

**MICRO SWARM BOTS

**Many little bots cut the branches and clear the trunk. The trunk is now easier to fell and fine shavings fertilise the forest soil.

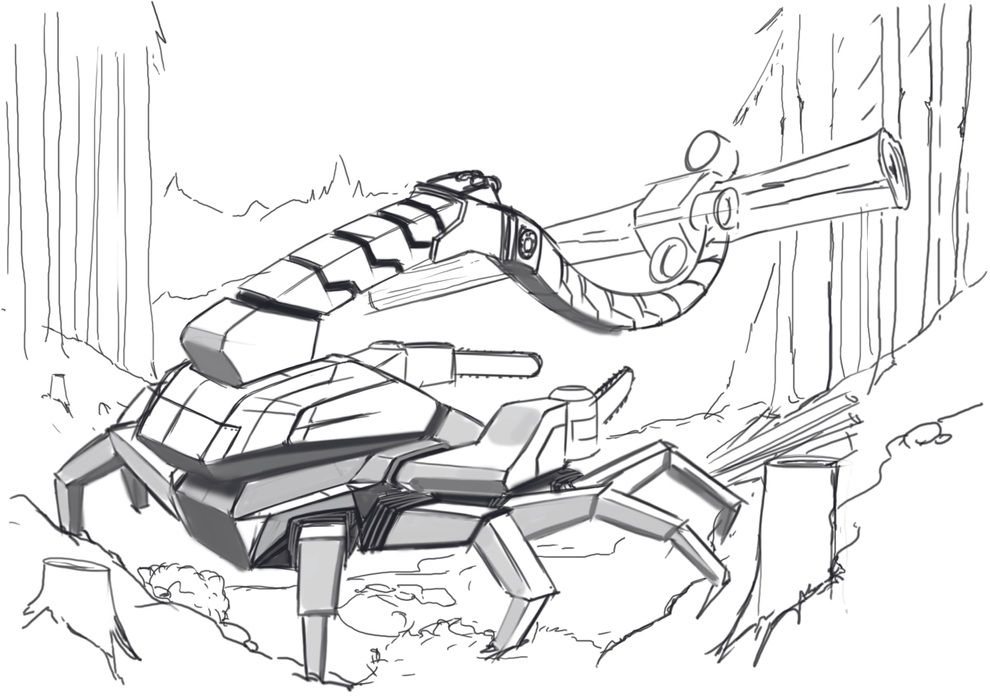

**REMOTE HARVESTER SCORPION

**Its legs cling to the ground in even impassable terrain. Less soil compaction with maximum off-road mobility. Remote-controlled via operator.

**LIGHT VEHICLE

**The trunk is unloaded before felling by a "trolley" running along the trunk. Does not have to carry the weight with branches and is self-sufficient or remote controlled.

2. Manual Harvesting

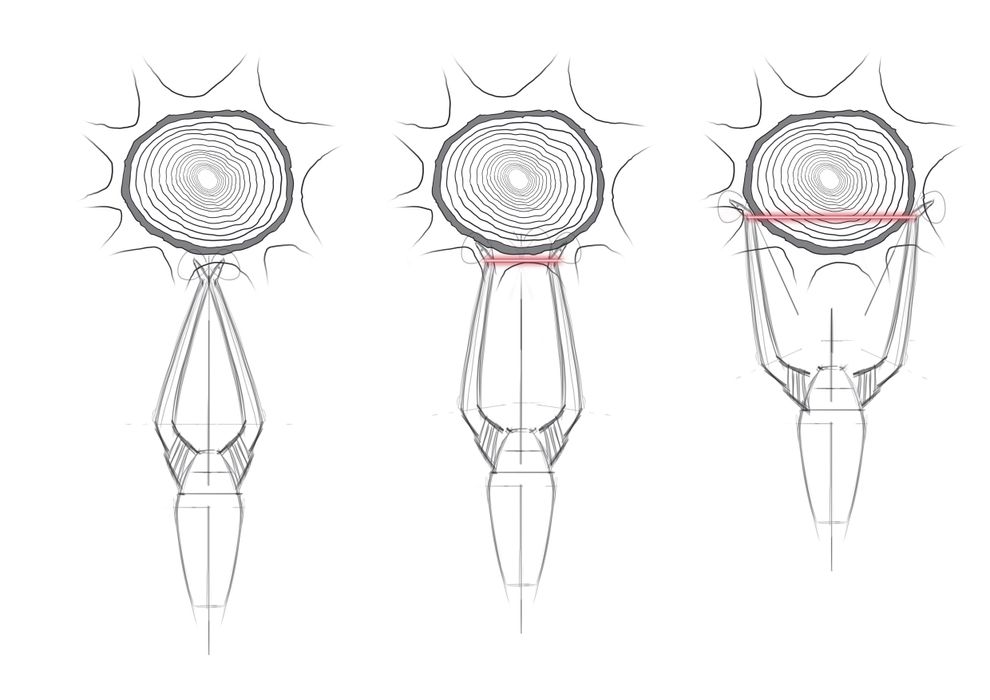

**LASERCUTTER

**The lasercutter shows a hologram for the right tree and the optimal cut path. The worker benefits from the Inflatable Hand-Fit.

**THE LASER UNIT

**The laser is always concealed and cannot escape. The laser arms adapt to the trunk contour.

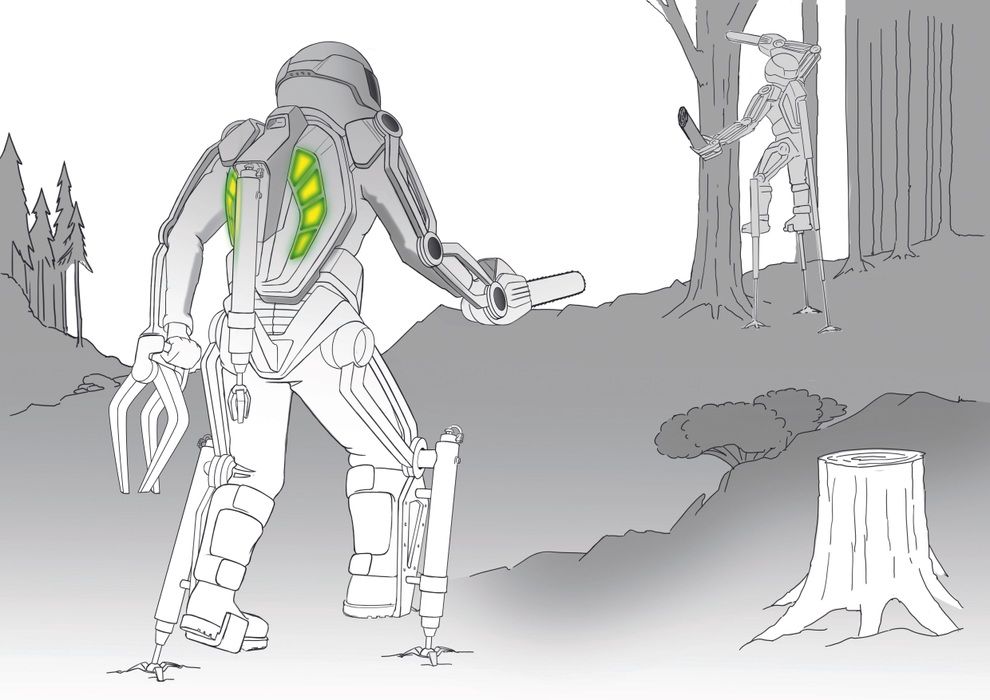

**EXO-SKELETT

**The advantage of this scenario is the use of interchangeable tools, which facilitate heavy work in difficult terrain. The Exo-skeletons have a telescopic lifting device with secure footing due to its three-point support. A helium3 plasma fuel cell could be used as an energy source for an electric saw

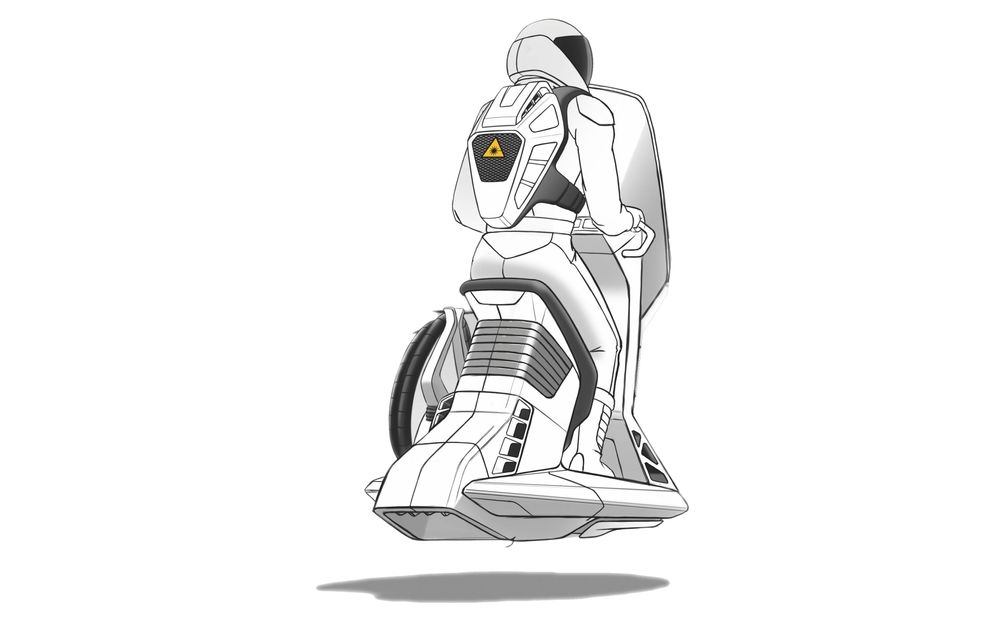

**WALLDAKERS

**If necessary, a forestry worker personally moves out with a soil-protecting hover vehicle.